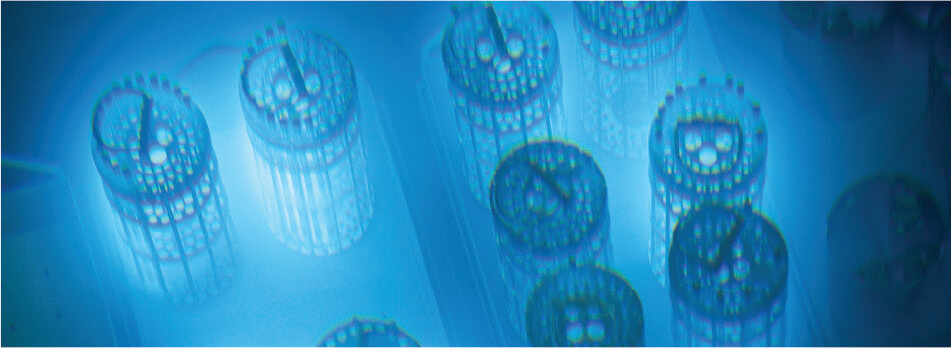

Gammabestrahler werden mit Kobalt-60 betrieben,

einem Isotop, das Gammastrahlung erzeugt. Gammastrahlung ist eine Form von elektromagnetischer Energie, die sich durch tiefe Durchdringung auszeichnet, wodurch sie Mikroorganismen im gesamten Produkt und in der Verpackung bei niedriger Temperatur und ohne Rückstände effektiv abtötet.

Lassen Sie uns Ihr Projekt gemeinsam starten

Kontakt aufnehmen

Gammabestrahlung ist hocheffektiv bei der Behandlung einer breiten Palette von Medizinprodukten, Arzneimitteln, Lebensmitteln und kommerziellen Produkten und geeignet, die Eigenschaften vieler verschiedener Materialarten zu verbessern.

Die Gammasterilisation mit Kobalt-60 stützt sich auf jahrzehntelang entwickelte Wissenschaft, Technologie und Normen, die Sicherheit, Zuverlässigkeit und Wirksamkeit gewährleisten.

Für außergewöhnliche Präzision und Wiederholbarkeit fragen Sie uns nach:

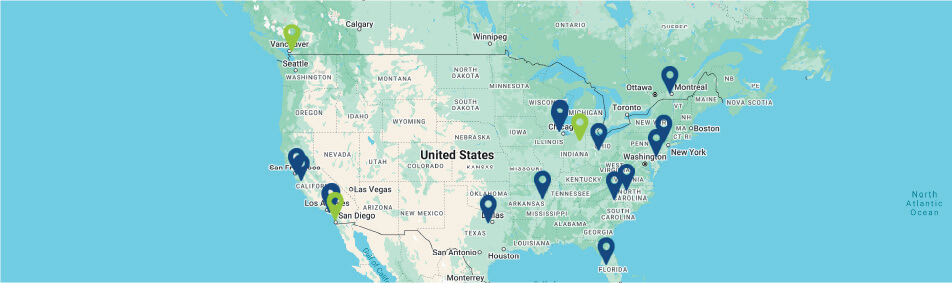

Mit einem großen globalen Netzwerk und jahrzehntelanger Erfahrung in der Branche ist die Gammabestrahlung nach wie vor eine ideale Sterilisationstechnologie für medizinische Einwegprodukte, pharmazeutische Produkte, Lebensmittel und andere Produkte.

Das Netzwerk aus nahezu 300 Gammabestrahlungseinrichtungen, das sich im Laufe der langen Geschichte der Branche etabliert hat, bietet solide Kapazitäten für Lieferketten, die auf diesen kritischen Sterilisationsschritt angewiesen sind, um die Sicherheit der Produkte für Patienten und Gesundheitsdienstleister zu gewährleisten.

Seit 2015 wurden mehr als 20 neue Bestrahlungseinrichtungen in 10 Ländern gebaut. Unser Schwesterunternehmen Nordion, seit mehr als 70 Jahren führender Anbieter von Kobalt-60, ist an laufenden Projekten zum Bau weiterer Einrichtungen beteiligt, da die Gammakapazität parallel zur Nachfrage weiter wächst.

Nordion, unser Schwesterunternehmen, investiert kontinuierlich und in erheblichem Umfang in den Erhalt der heimischen Kobalt-60-Quellen und erweitert und diversifiziert gleichzeitig sein Netzwerk.

Wir bei Steringetics wollen auf die wachsende Nachfrage nach Sterilisationslösungen reagieren, um gemeinsam mit unseren Kunden Gefährdungen für die menschliche Gesundheit zu beseitigen. Wir investieren fortlaufend in erheblichem Umfang in unser globales Netzwerk, um auf die zunehmenden Bedürfnisse unserer Kunden im Bereich Sterilisation als einen wichtigen Schritt in ihren Produktentwicklungsprozessen zu reagieren.

Die hohe Dichte von Kobalt-60 ermöglicht es dem Radioisotop, etwa 20 Jahre lang aktiv zu sein. Mithilfe von Recyclingprogrammen lassen sich mehr als 99 % des Materials in neue Quellen zurückführen. Der geringe Kohlenstoff-Fußabdruck, der mit dem Transport einhergeht, wird über die Lebensdauer des Produkts amortisiert.

Die Gammasterilisation bietet gegenüber anderen industriellen Sterilisationstechnologien erhebliche ökologische Vorteile. Die Verwendung von Kobalt-60 als Quelle ionisierender Strahlung geht mit einem 15-mal geringeren Stromverbrauch und 12-mal geringeren Treibhausgasemissionen als bei Röntgenanlagen einher, die große Mengen an Strom verbrauchen, der oft durch nicht erneuerbare Technologien erzeugt wird.

Einrichtungen für Gammabestrahlung weltweit durchsuchen

Standorte finden

Wir sind ein weltweit führender Anbieter von ausgelagerten terminalen Sterilisations- und Bestrahlungsdienstleistungen für die Bereiche Medizinprodukte, Pharmazeutik, Lebensmittelsicherheit und erweiterte Anwendungen sowie von Expert Advisory Services. Wir gehen umfassend auf Ihre Bedürfnisse ein, vom Produktdesign bis zur Vermarktung, um die Sicherheit Ihrer Produkte und Verfahren sicherzustellen.